Decide up a button mushroom from the grocery store and it squishes simply between your fingers. Snap a woody bracket mushroom off a tree trunk and also you’ll battle to interrupt it. Each extremes develop from the identical microscopic constructing blocks: hyphae – hair-thin tubes made principally of the pure polymer chitin, a troublesome compound additionally present in crab shells.

As these tubes department and weave, they kind a light-weight however surprisingly robust community referred to as mycelium. Engineers are starting to research this community to be used in eco-friendly supplies.

Filaments referred to as hyphae are a mushroom’s assist buildings each above and under floor, and the mycelium community hyperlinks a number of mushrooms collectively.

Milkwood.internet/Flickr, CC BY-NC-SA

But even inside a single mushroom household, the power of a mycelium community can differ broadly. Scientists have lengthy suspected that how the hyphae are organized – not simply what they’re made from – holds the important thing to understanding, and finally controlling, their power. However till not too long ago, measurements that instantly hyperlink microscopic association to macroscopic power have been scarce.

I’m a mechanical engineering Ph.D. scholar at Binghamton College who research bio-inspired buildings. In our newest analysis, my colleagues and I requested a easy query: Can we tune the power of a mushroomlike materials simply by altering the angle of its filaments, with out including any more durable elements? The reply, it seems, is sure.

2 edible species, many tiny checks

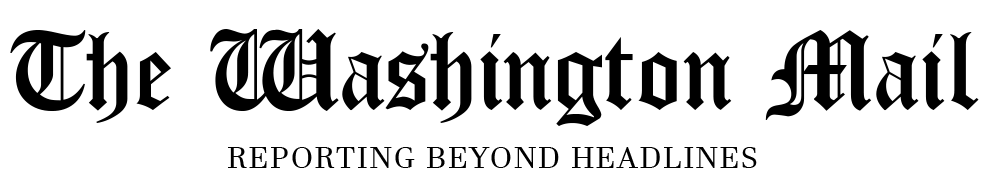

In our examine, my workforce in contrast two acquainted fungi. The primary was the white button mushroom, whose tissue makes use of solely skinny filaments referred to as generative filaments. The second was the maitake, additionally referred to as hen-of-the-woods, whose tissue mixes in a second, thicker kind of hyphae referred to as skeletal filaments. These skeletal filaments are organized roughly in parallel, like bundles of cables.

The 2 varieties of mushrooms used within the examine: The white button mushroom is monomitic, proven on the left, which means it has just one kind of hyphae. The maitake is proven on the correct, and is dimitic, which means it has two varieties of hyphae.

Mohamed Khalil Elhachimi

After gently drying the caps and stems to take away any water, which might soften the fabric and skew the outcomes, we zoomed in with scanning electron microscopes and examined the samples at two very totally different scales.

First, we examined macro-scale compression. A motor-driven piston slowly squashed every mushroom whereas sensors recorded how arduous the pattern pushed again – the identical approach you may squeeze a marshmallow, solely with laboratory precision.

Then we pressed a diamond tip thinner than a human hair into particular person filaments to measure their stiffness.

The white mushroom filaments behaved like rubber bands, averaging about 18 megapascals in stiffness – just like pure rubber. The thicker skeletal filaments in maitake measured round 560 megapascals, greater than 30 occasions stiffer and approaching the stiffness of high-density polyethylene – the inflexible plastic utilized in chopping boards and a few water pipes.

The 2 mushrooms examined embrace the maitake, left, and the button mushroom.

Lance Cheung/USDA and edenpictures/Flickr, CC BY

However chemistry is barely half the story. After we squeezed whole chunks, the path we squeezed in mattered much more for the maitake. Urgent according to its parallel skeletal filaments made the block 30 occasions stiffer than urgent throughout the grain. Against this, the tangled filaments in white mushrooms felt equally comfortable from each angle.

A digital mushroom and twisting the threads

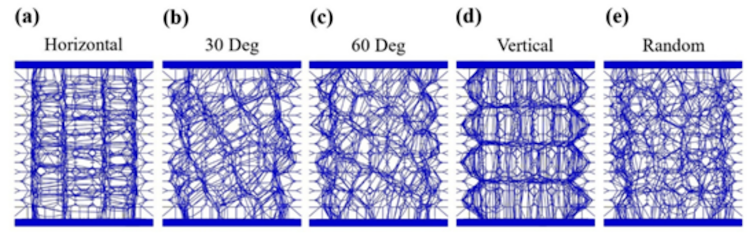

To separate geometry from chemistry, we transformed snapshots from the microscope into a pc mannequin utilizing a 3D Voronoi community – a sample that mimics the partitions between bubbles in a foam. Consider ping-pong balls crammed in a field: Every ball is a cell, and the partitions between cells turn into our simulated filaments.

We assigned these filaments by the stiffness values measured within the lab, then nearly rotated the entire community to angles of 0 levels, 30 levels, 60 levels, 90 levels and fully random.

Horizontal (0 levels) filaments flexed like a spring mattress. Vertical (90 levels) filaments supported weight virtually as firmly as dense wooden. Merely tilting the community to 60 levels almost doubled its stiffness in contrast with 0 levels – all with out altering a single chemical ingredient.

The researchers modeled buildings with totally different fiber orientations to see that are the strongest: (a) represents a horizontal fiber orientation, (b) a 30-degree fiber orientation, (c) a 60-degree fiber orientation, (d) a vertical fiber orientation, and (e) a random fiber orientation.

Mohamed Khalil Elhachimi

Mainly, we discovered that orientation alone may flip a mushy sponge into one thing that stands as much as critical strain. That implies producers may make robust, light-weight, biodegradable components – reminiscent of shoe insoles, protecting packaging and even inside panels for vehicles – just by guiding how a fungus grows relatively than by mixing in more durable components.

Greener supplies – and past

Startups already develop “leather” constituted of mycelium – the threadlike fungal community – for purses, and mycelium foam as a Styrofoam substitute.

Guiding fungi to put their filaments in strategic instructions may push efficiency a lot greater, opening doorways in sectors the place strength-to-weight ratio is king: suppose sporting items cores, building-insulation panels or light-weight fillers inside plane panels.

The identical digital device package additionally works for metallic or polymer lattices printed layer by layer. Swap the filament properties within the mannequin, let the algorithm decide the perfect angles, after which feed that format right into a 3D printer.

Someday, engineers may dial up an app that claims one thing like, “I need a panel that’s stiff north-south but flexible east-west,” and this system may spit out a filament map impressed by the common-or-garden maitake.

Our subsequent step is to feed hundreds of those digital networks right into a machine studying mannequin so it will probably predict – and even invent – filament layouts that hit a focused stiffness in any path.

In the meantime, biologists are exploring low-energy methods to coax actual fungi to develop in neat rows, from steering vitamins towards one aspect of a petri dish to making use of light electrical fields that encourage filaments to align.

This examine taught us that you simply don’t at all times want unique chemistry to make a greater materials. Generally it’s all about the way you line up the identical previous threads – simply ask a mushroom.