The phrase “local” has turn into synonymous with sustainability, whether or not it’s meals, garments or the supplies used to assemble buildings. However whereas shoppers can in all probability go to a neighborhood lumberyard to purchase lumber from sustainably grown bushes reduce at close by sawmills, nobody asks for native glass.

In the event that they did, it will be exhausting to provide a solution.

The uncooked supplies that go into glass – silica sand, soda ash and limestone – are pure, however the sources of these supplies are hardly ever identified to the client.

The method by which sand turns into sheets of glass is usually removed from clear. The sand, which makes up over 70% of glass, might come from a faraway riverbed, lakeshore or inland limestone outcrop. Sand with at the least 95% silica content material known as silica sand, and solely the purest is appropriate for architectural glass manufacturing. Such sand is present in restricted areas.

Klondike Park, exterior St. Louis, was as soon as a mine for St. Peter sandstone, utilized in glass manufacturing. This is likely one of the few U.S. areas with 99% pure silica.

Aki Ishida

If the glass is colorless, its potential sources are much more restricted, as a result of colorless low-iron glass – popularized by Apple’s flagship shops and luxurious towers around the globe – requires 99% pure silica sand.

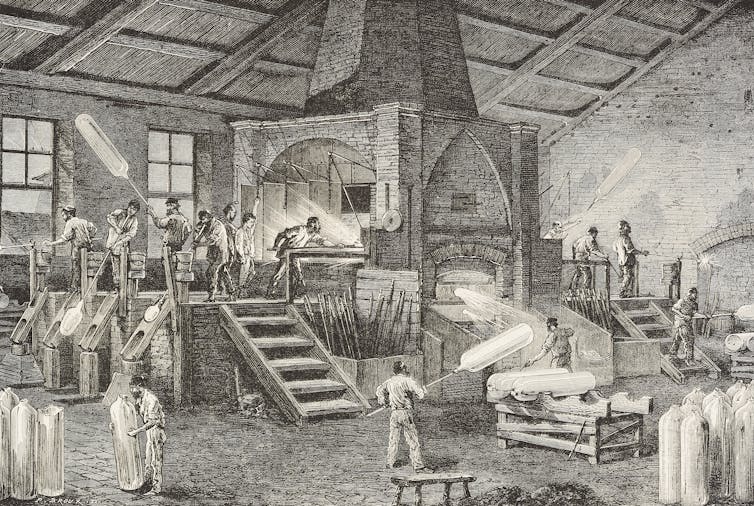

Glass manufacturing in Venice

The mysteries of glass manufacturing have historic precedent that may be traced again to commerce secrets and techniques of the Venetian Empire.

Venice, significantly the island of Murano, turned the middle for glass manufacturing largely attributable to its strategic location for importing uncooked supplies and manufacturing know-how and exporting coveted glass objects.

From the eleventh to the sixteenth centuries, the secrets and techniques of glassmaking had been protected by the Venetians till three glassmakers had been smuggled out by King Louis XIV of France, who utilized the know-how to create the Palace of Versailles’ Corridor of Mirrors.

The Palace of Versailles’ famed Corridor of Mirrors was made by glass artisans skilled by the Venetians.

Myrabella/Wikimedia Commons, CC BY-SA

Venice was an in any other case unlikely location for glassmaking.

Neither the first supplies of sand and soda ash (sodium carbonate) nor the firewood for the medieval Venetian glassmakers had been discovered within the metropolis’s instant neighborhood. They had been transported from the riverbeds of the Ticino River in Switzerland and the Agide River, which flows from the Austria-Switzerland border to the Adriatic Sea south of Venice. Soda ash, which is required to decrease the melting level of silica sand, was introduced from Syria and Egypt.

So Venetian glass manufacturing was not native; it was depending on valuable sources imported from afar on ships.

Glassmaking has been a labor- and fuel-intensive course of. This engraving from 1877 reveals the manufacturing of glass cylinders, that are reduce and unrolled to make glass sheets.

L’Illustrazione Italiana, No 51/De Agostini by way of Getty Photos

Rising demand for low-iron, seamless glass

Prior to now few a long time, low-iron glass, identified for its colorlessness, has turn into the up to date image of high-end structure. The glass seems to vanish.

Low-iron glass is constructed from ultrapure sand that’s low in iron oxide. Iron causes the inexperienced tint seen in abnormal glass. In structure, low-iron glass doesn’t have an effect on the efficiency – solely the looks. However it’s prized.

Most glass has a greenish tint, attributable to iron oxide within the sand. Low-iron glass is extra clear, however the elements come from unique sand mines, which may imply extra transportation emissions, significantly for giant panels produced in a restricted variety of factories.

Bluecinema/E+ by way of Getty Photos

Within the U.S., this sort of sand is present in just a few areas, primarily in Minnesota, Wisconsin, Illinois and Missouri, the place sand as white and advantageous as sugar – thus referred to as saccharoidal – is mined from St. Peter sandstone. Different areas the place it may be discovered around the globe embrace Queensland in Australia and elements of China. Much less pure sand will be purified by strategies akin to acid washing or magnetic separation.

Maybe no company has popularized low-iron and seamless glass in structure greater than the know-how big Apple.

Glass has turn into essentially linked with Apple’s merchandise and structure, together with its flagship shops’ costly and daring experiments in architectural makes use of of glass.

Apple’s first showroom, accomplished in Soho in New York in 2002, showcased all-glass stairs that had been strengthened with hurricane- and bullet-resistant plastic interlayers sandwiched between 5 sheets of glass. The treads connect to all glass partitions with a hockey puck-size titanium {hardware}, making each the glass stairs and the consumers seem to drift.

Apple’s New York flagship retailer, dubbed the Dice, was inbuilt 2006 with 90 panels of low-iron glass, then rebuilt in 2011 with 15 panels.

Ben Hider/Getty Photos

The corporate’s iconic flagship retailer close to New York’s Central Park is an all-glass dice measuring 32½ ft (10 meters) on both sides and serving as a vestibule to the shop beneath. The primary model was accomplished in 2006 utilizing 90 panels, which was a technical feat. Then, in 2011, Apple reconstructed the dice in the identical location, identical dimension, however with solely 15 panels, minimizing the variety of seams and {hardware} whereas maximizing transparency.

Right this moment, low-iron glass has turn into the usual for high-profile structure and people who can afford it, together with the “pencil towers” in Manhattan’s Billionaires’ Row.

New high-rises just like the supertall towers in New York’s Billionaire’s Row are largely clad flooring to ceiling in glass.

Aerial_Views/E+ by way of Getty Photos

Glass’s local weather influence

Glass partitions frequent in high-rise buildings right this moment produce other drawbacks. They assist to warmth up the room throughout more and more scorching summers and contribute to warmth loss in winter, growing dependence on synthetic cooling and heating.

The glassmaking course of is vitality intensive and depends on nonrenewable sources.

To convey sand to its molten state, the furnace have to be heated to over 2,700 levels Fahrenheit (1,500 levels Celisus) for so long as 50 hours, which requires burning fossil fuels akin to pure fuel, releasing greenhouse gases. As soon as heated to that temperature, the furnace runs 24/7 and isn’t shut down.

Glass producer Pilkington reveals how glass is made.

The soda ash and limestone additionally launch carbon dioxide throughout melting. Furthermore, glass manufacturing requires mining or producing nonrenewable pure sources akin to sand, soda ash, lime and gasoline. Transporting them additional will increase emissions.

Manufacturing and fabrication of extra-large glass panels depend on specialised tools and happen solely at a restricted variety of vegetation on the planet, that means transportation will increase the carbon footprint.

Architectural glass can also be troublesome to recycle, largely because of the labor concerned in separating glass from the constructing meeting.

Though glass is touted as infinitely recyclable, solely 6% of architectural glass is downcycled into glass merchandise that require much less purity and precision, and virtually none is recycled into architectural glass. The remaining leads to landfills.

The growing demand for glass that’s colorless, further massive and seamless contributes to glass’s sustainability downside.

This 99% pure silica, a sugarlike sand, comes from a St. Peter sandstone mine as soon as used for glassmaking. It’s now Klondike Park in St. Charles County, Mo.

Aki Ishida

How can we make glass extra sustainable?

There are methods to scale back glass’s environmental footprint.

Researchers and corporations are engaged on new forms of glass that might decrease its local weather influence, akin to utilizing supplies that decrease the quantity of warmth essential to make glass. Changing pure fuel, usually utilized in glassmaking, with less-polluting energy sources may scale back emissions.

Low-e coatings, a skinny coat of silver sprayed onto a glass floor, will help scale back the quantity of warmth that reaches a constructing’s inside by reflecting each the seen mild and warmth, however the coating can’t totally get rid of photo voltaic warmth acquire.

Individuals may alter their requirements and settle for smaller and fewer ultraclear panels. Consider the inexperienced tint not as impure however pure.